DOSF:

Fluid Dispenser is a patented engineered device used in the automotive industry in differentiated models for each type of engine and fuel.

Application:

In 4,to 10 cylinder engines of any version: With carburetor, T b i., F. i., Turbo, 4x4, with or without super charger, and various manufacturers, by at least 10 brands around the globe: GM., Ford, Chrysler, Nissan, Toyota, etc.

Fuels:

In principle it works with all kinds -octane- of gasoline, gas LP, and diesel.

Function:

Dispenses pressure changes in the engine taking full advantage of the entire energetic potential at hand.

Benefits:

They are immediate and readily notable: Quick start of the engine; Better combustion and/or engine displacement; softer, powerful, and quite, whenever it is required. Therefore, it reduces fuel expenses/use, while improving performance; 20% to 25%. Reduces production of badly burnt granules and emission of toxic fumes into the environment, 60 to 65%, due both to the truly burnt energetic and the energetic that is saved or unused. Therefore the work load of engines in general, and their essential parts last a lot longer.

Manufacture:

Made of steel and aluminum to favor long life and little maintenance. Measurements: 3 cm in diameter x13 cm long. Total weight: 247 gr.

Maintenance:

The module only requires to be washed with gasoline and air, every 12,500 miles, or until a decrease of said benefits is felt.

Warranty:

2 years or 62,000 miles, whatever takes place first, attached to the same engine and having followed the manufacturers instructions.

Technical Support:

Certified by field tests and controlled bench tests controlled by academics and specialists of institutions recognized worldwide:

- Universidad Nacional Autónoma de México..-

- UNAM Research and Development Thermal Engineering Centre.

Instituto Politécnico Nacional.-- IPN Technological Research and Innovation Centre CIITEC.

National Commission for Energy Savings.-- National Commission of Electricity

Daimler Chrysler of México,- among many other acknowledgements, and thousands of satisfied users in the country.

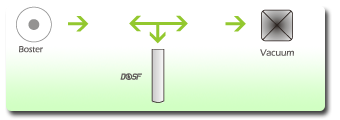

Installation.

Study the ideal place and manner of the installation, the module should be vertical and the upper screen should face the sun, to proceed as follows:

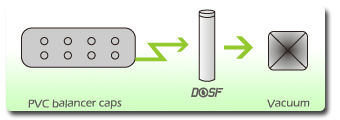

a) In engines provided with PVC: Control Valve Pollution.

Detach the hose coming from the PVC to the engine's vacuum, balancer cap, insert it in either one of the intakes of the module and with a short section of hose, 10 cm, attach the other higher intake of the device to the vacuum.

Avoid bents and kinks in the hoses, facilitate the free and straight passage of fluids, and lastly, connect the wire of the recipient to the engine's power line before: starting the engine, air conditioning, headlights or signals, holding the module at the end with a plastic band onto a safe place, if required.

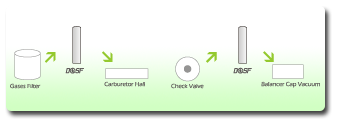

b) In engines with out PVC or low suction in the vaccum.

Use the vacuum hose of the gas filter, and bridge the DOsF 10 cm away from the carburetor hall. En V.W. carburetor, place the check valve of the booster with 40 cm of hose, to the end, insert a higher intake of MDF, to the other intake of the device attach a 15 cm long section of hose, connect it to the vacuum, on the balancer cap, with clamp and attach the device to a safe place, isolating the manifold hose.

c) In engines with no PVC:

Use the booster line hose to the engine's vacuum.

Images Installation